Motorcycle Mechanic Salary Guide

Learn about the 10 states with the top median motorcycle mechanic salary rankings in the U.S.! Get details on what it takes to earn a living as a technician.

Key Points

There are a number of key components that make up your motorcycle, and each one helps keep it operational on the road. One of the major parts is the transmission. Before getting into what a transmission is and how it works, let’s start with the basics.

In any vehicle (motorcycle or otherwise) a transmission has two main purposes:

Internal combustion engines have a relatively narrow power band. If the engine speed, measured in revolutions per minute (RPM), is either too high or too low, engine power and efficiency will not be optimal. Transmissions contain multiple gear ratios, which keep the engine RPM in an ideal range and allow the vehicle to accelerate from a stop, cruise at high speed and everything in between.

A motorcycle transmission accomplishes the same two main objectives mentioned above. However, it is packaged in a compact manner, so it remains small and lightweight.

Many Harley-Davidson® motorcycles use a stand-alone transmission fastened to the engine and driven by an external primary drive. Most other motorcycles use a design where the transmission and engine are one complete unit, as seen in the image below:

Image credit: Suzuki Motor Corp.

Automatic transmissions exist in motorcycles in a few forms:

An automatic motorcycle transmission completes the same tasks as a manual transmission. It allows the vehicle to come to a full stop without stopping the engine and requiring the rider to shift through a range of gear ratios for multiple speeds.

While automatic transmissions have made their way to the market, manual motorcycle transmissions are still a staple in the biking world. In fact, most motorcycles feature manual transmissions operated by a foot lever and a hand clutch.

Manual transmissions offer an engaging experience with tactile feedback. Typically, they follow a standardized gear pattern—one down for first gear and the rest up for subsequent gears, with neutral between first and second. This allows riders to smoothly transition through gears.

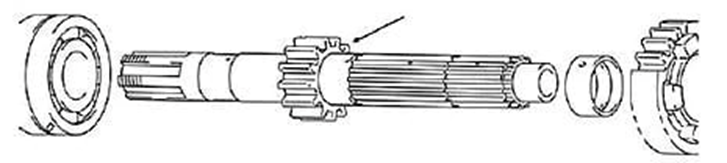

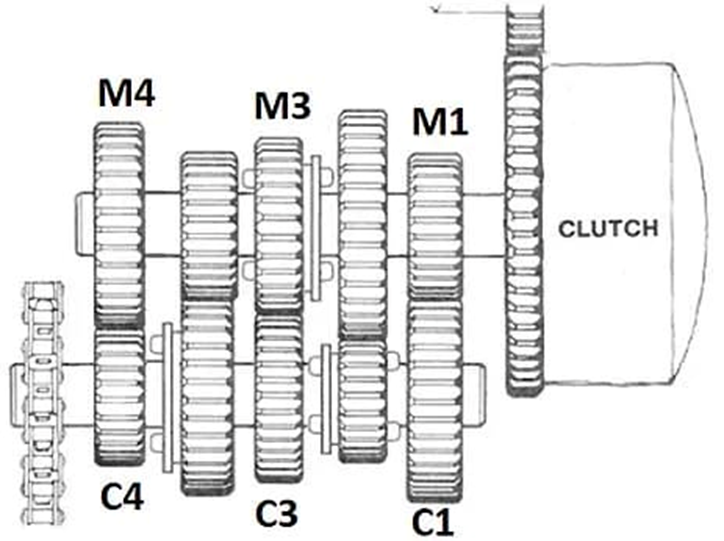

Motorcycle transmissions use a series of internal and external parts to maintain an ideal RPM range. These include:

Image credit: Suzuki Motor Corp.

Image credit: Kawasaki Motors Corp. USA

Image credit: Suzuki Motor Corp.

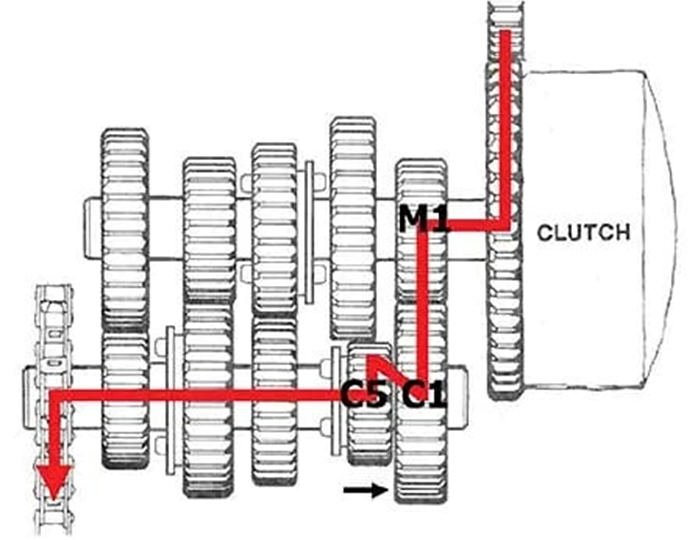

Analyzing a power flow diagram is a great way to understand how a motorcycle transmission works. This power flow diagram shows what happens when a motorcycle is in first gear:

Image credit: Yamaha Motor Corp. USA

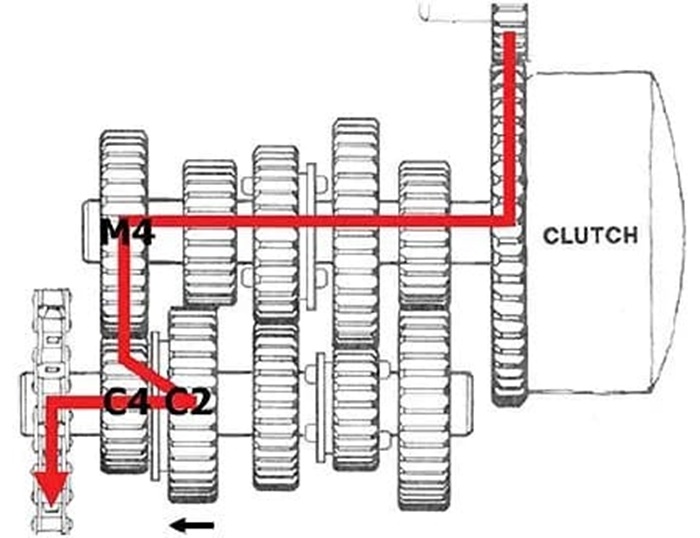

This power flow diagram shows what happens to the transmission when the motorcycle is in fourth gear:

Image credit: Yamaha Motor Corp. USA

And this power flow diagram shows what happens to the transmission when the motorcycle is in neutral:

Image credit: Yamaha Motor Corp. USA

While modern motorcycles are reliable and well-built, transmission issues may still occur at some point. It is common for a motorcycle owner to complain about:

A skilled technician can determine the difference between a transmission issue and a clutch issue, as both can present similar concerns for a motorcycle owner.

Gaining access to a motorcycle transmission can be a challenge and a time-consuming process. A motorcycle technician will often eliminate all other possible causes of the complaint before “splitting the cases” to access transmission components.

Read: What Is a Small-Engine Mechanic?

Advancements in motorcycle transmission technology include semi-automatic gearboxes and dual-clutch transmissions (DCT). These innovations enhance rider experience by offering smoother gear shifts and improved performance without the need for a manual clutch.

It’s all about smooth and timely gear shifts, which comes with practice. Maintaining a steady speed, avoiding rapid acceleration and deceleration and using the highest gear possible without straining the engine can improve fuel efficiency.

Motorcycles typically have a range of four to six gears, though some models may have as few as three or as many as seven. The number of motorcycle gears can vary based on the type and purpose of the vehicle, such as sport bikes, cruisers or touring bikes.

Not all manual motorcycles have the same gear pattern, but most modern motorcycles follow a standard pattern of one down for first gear and the rest up. Neutral is typically between first and second gear. However, some racing motorcycles may use a reversed pattern where the rider clicks down to upshift, allowing for quicker and more efficient gear changes during high-speed maneuvers.

In the 48-week Motorcycle Technician Training program at UTI, students can learn the foundations of motorcycle, all-terrain vehicle (ATV), side-by-side and personal watercraft maintenance to prepare for an exciting career as a technician.1.7

UTI students can learn complex topics, like motorcycle transmission configurations in program courses. This includes disassembling and troubleshooting transmission issues to become familiar with how they work and what to do if something goes wrong.

To learn more, request information to talk with an Admissions Representative!

Universal Technical Institute of Illinois, Inc. is approved by the Division of Private Business and Vocational Schools of the Illinois Board of Higher Education.